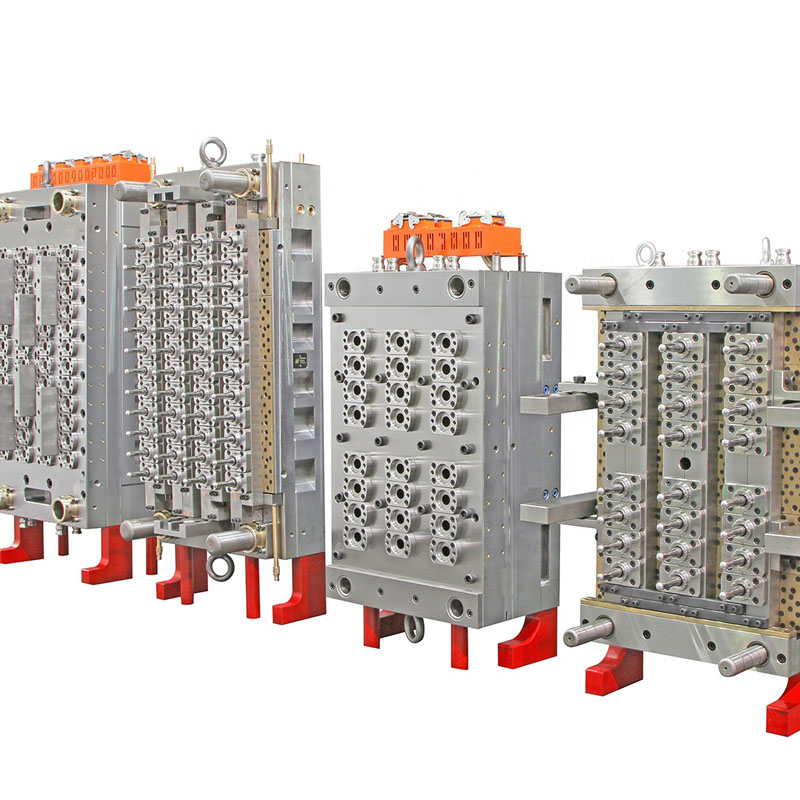

12 Cavities Hot Runner Plastic Injection Needle Valve Pet Preform Mould

12 Cavities Hot Runner Plastic Injection Needle Valve Pet Preform Mould

Apex company warmly welcome friends from home and abroad to establish a wide rang of cooperation, mutual benefit and common development.

| Mold Model | 12cavity pet preform mould |

| Preform Neck | 28mm, 30mm, 38mm |

| Preform Weight | according to customer's requirement |

| Runner | Hot runner |

| Core Material | S136 |

| Cavtiy Material | S136 |

| Screw Neck Material | S136 |

| Mold Base | 4CR13 Steel |

| Mold Size | 610*320*500 |

| Cycle time | different weight with the different cycle time |

| Mold Life | 3-5millions |

| Scope of Application | water bottle |

| Delivery time | 50-60days |

product Description

2024 New Design High Quality 12 Cavity PET Preform Mould

packaging &delivery

packaging :standard export wooden case

delivery time:shipping in 50days after payment

application:preform mold is installed on injection machine and used for producing preform,such as 5gallon preform,28mm pco 1810 mould,1881 preform mould, 38mm 2start preform mould,38mm 3start preform mould,48mm pet preform moulds,PP preform mould,beverage preform mould,water bottle mould,oil bottle preform mould,preform mould with valve gate,preform mould with short tail,preform with long tail,mineral bottle preform mould,edible oil bottle preform mould,3gallon preform mould,5gallon preform mould,preform with different weight,preform mould with 1 to 96cavities.etc.

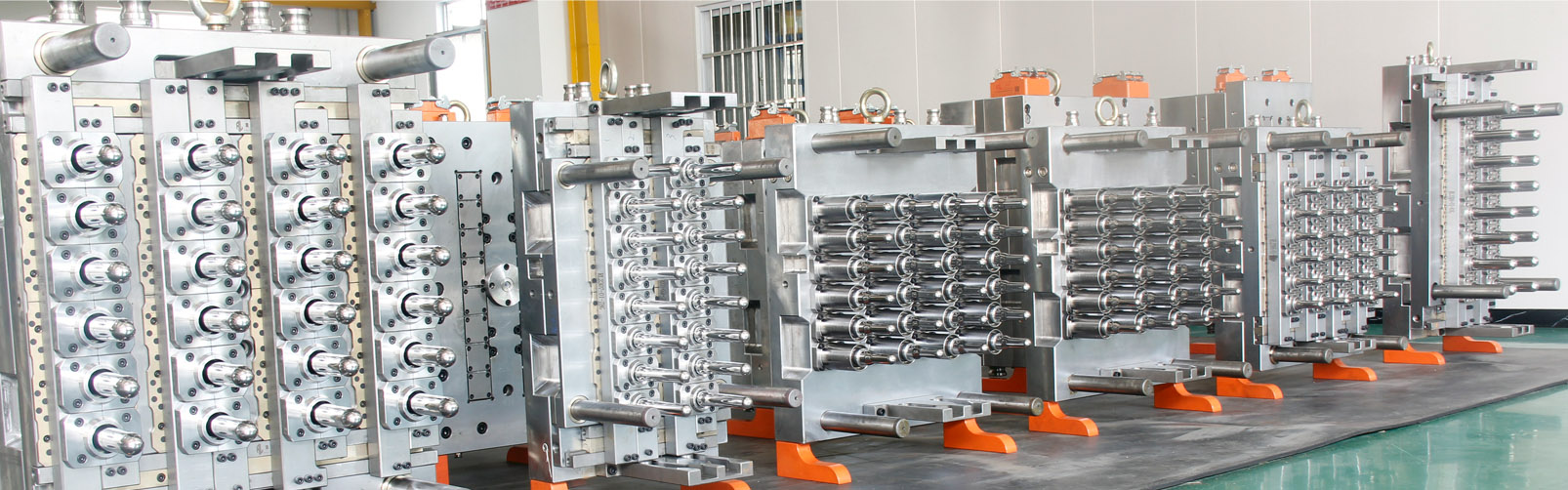

PET Preform Mould, Preform Mold Maker In China

For over 10 years, APEX has been the go-to source for reliable, affordable PET preform moulds. Our experienced team uses modern technology combined with the highest quality materials to create molds that are durable and cost-effective.We have earned the trust of both local and international customers, thanks to our commitment to customer satisfaction. Our staff is continuously refining and innovating the production process to ensure the best quality results.

Our confidence in the quality of our PET preform moulds is backed by more than a decade of experience, and we guarantee that our products will meet the needs of our customers. If you’re searching for quality preform molds at competitive prices, APEX is the perfect partner.

Rich experience in preform mold manufacturing

APEX plastic mould company has accumulated significant experience in the plastic injection moulding industry over the last ten years in China. As a result, we have developed substantial knowledge and expertise that allow our company to offer the customers the highest level of skills, knowledge, and dedication in the preform mould market.

No doubt about it, APEX can manufacture a complete set of PET preform moulds on time and accurately, at the best possible PET preform moulds prices.

GET A FREE QUOTE-40% LOWER ,15 DAYS LESS

Our company has gained extensive skill and expertise in preform mould, allowing clients to trust that they will receive top-class service, efficiency, and commitment.With the capacity to build a full set of PET preform moulds promptly, accurately and cost-effectively no matter how elaborate, APEX is ready to meet any customer needs.

Beyond this, we are also able to design and make each PET preform to customers’ particular specifications, as well as provide printing options on each one.

Strong R & D System

A good preform project development needs consider molding and blowing system together seriously. By professional analysis software and rich making experience, we could evaluate preform shape and bench rate well to avoid future mistakes. Think in future, and we honored a more thinking will be make finished preforms more competitive in market.

Standard Mold Component And Brand Spare Parts

Precision tooling machines ensures each inserts and mold component be in standard, it will be easy for maintenance in future. And with brand spare parts, preform users result will be better for practice.

A. Capacity of Research and Development

APEX has a powerful team for research and development, which is capable of manufacturing the pet perform molds with 1 cavity to 96 cavities including the pet preform injection molding system. At the same time we can manufacture pet perform molds especially according to customers' injection molding machines. We also design cold parts, hot runners and other main exchangeable components to fix on the imported perform molds.

B. Mould Features:

1. Features of the perform mold. No cutting of valve gate is employed to reduce the labor cost.

2. Advanced hot runner system assures lower level of AA value.

3. Reasonable- designed cold water channels increase cooling effect and shorten the cycle time.

C. Material

1. The main components of perform molds are made of S136 material (Sweden ASSAB).

2. The mold base is made of imported P20. plate method avoids corrosion efficaciously and assures long life service of the perform molds.

3. German Vacuum stove is imported for heat treatment of the components, which assures the hardness of components HRC45-HRC48.

D. Advanced Processing Equipment

Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. All of these increases processing precision, good interchangeability and low eccentricity ≤0.10mm (perform length≤100).

E. Electric Heating Components

1. German Hotset heating components.

2. German intelligent temperature controller (PID continuous power controlling).

3. Offering temperature controller and voltage controller according to customers' requirement

F. Perfect Inspection Method.

Inspection tools include projector, hardness tester, stress tester, eccentric tester, electric balance and other inspection tools. The screw neck is made and inspected strictly by the standard of Coca cola and the screw neck has been up to the standard of Coca cola.

G. After-Sales Service

Technologists professional in after-sales line and excellent credit assures stable operation of the machines.

APEX provides not only a mold, but a fine plastic PET preform injection molding solution. It’s like a complete preform molding line contained PET preform molds (Preform type ROPP, ALASKA, PCO1810, PCO1881, BPF, 30/25, 29/25, 26/22, 38mm, 48mm, 50-150mm etc), special PET injection molding machine, other accessories such like dehumidify and dryer, auto loader, water tower, chiller and so on. Besides, we will also provide detail factory plan, gas & water& electric plan and engineer service on customer’s factory for equipment installing, parameter adjusting, and operating & maintenance operation.

PET preform Mould Feature

- 1. Mould plates are 4G13 or P20 stainless steel with pre-hardening process. Core, cavity and neck screw are made of S136 high Strength, anti-corrosive stainless steel. Mould plate is completed by one-time processing to ensure the concentricity of moulding hole and guide bush, guaranteeing the compact structure of mould.

- 2. Spiral cooling design for each single core and cavity, it helps to lessen the cycle time, improving production efficiency and saving costs. Opening/closing pulling plate adopts bearing slide type to drop the preform with realiable structure. And it is a highly integrated process of slider, pushing plate and ejection. All sliding parts surface inlaid self-lubricating copper alloys to ensure low friction effecient and strong wear-resistant.

- 3. Self- lock individually for each cavity to guarantee high precision and less defect of the final preform production as well as convenient disassembly.

- 4. Off-center adjustment system to ensure preform thickness difference < 0.10mm. Adopting double cone positioning principle guarantees high manufacturing precision to ensure the product without appearing flash, different size, irregular and other defects.

- 5. Experienced designers design preform mould with UG, Pro-E according to the clients sample; Preform thickness and height is reasonably and perfectly designed to ensure the final bottles weight light but feel hard.

- 6. Hot runner valve gate system is perfect used; No need to cut preform tail and it would save labor costs.

- 7. Hot runner system uses China advanced brand or imported hot runner system brand such as Yudo/Mastip/Hasco etc. Each cavity has independent temperature control and heater system. It will prevent the white defects on the preform and improve the qualtiy of plastic products.

- 8. Customer service: one year free warranty, life-long technical support service.